In #theweekof, we get to have a look within the workweek of young professionals in Seed Valley.

Hi! My name is Jory, I am 26 years old and have been working at Bayer Crop Science in Enkhuizen for five years. After six months of working in the packaging department, I have now been working as an Operations Specialist at the cleaning department for 4.5 years. Together with my colleagues, we make sure the seeds are free of diseases and have a good germination capacity. Our daily job also includes removing light seeds, twigs, soil and other chaff particles. This way, we are responsible for ensuring that the vegetable seeds can be sent to customers in top condition. Today I’d like to show you how I contribute to that process!

How I ended up at Bayer

I joined Bayer through the president of my football club after I quit my studies. I liked it so much that I never left. All days are good days, it’s great fun with my colleagues and the working atmosphere is good. In addition, my work is very varied because I get to work with different machines every day. More about that later ;).

For the position of Operation Specialist, I did not do any relevant studies; I took a sports course before I started working for Bayer. After six months as a packer at Bayer, I started looking for something new. My colleagues knew I wanted something different and encouraged me to apply further within the company. That’s how I ended up in this position. I did take a course in seed physiology from Bayer. It is important to have knowledge of the product I work with, especially because each seed requires a different treatment.

I also try to keep developing myself in various areas, because my ambition is to become Team Lead. For instance, I took an English course, but I also join in on various ongoing projects at Bayer. In the process, I come into contact with colleagues from different departments in the company. Among other things, I am now involved in the ‘Seed Technology drying processes’ project. This way, I help think about the future of the company and in the meantime, I develop myself within the company.

A 'basic' clean

A little past 7, I get off my bike; I live in Grootebroek and am at work within minutes. All orders to be cleaned are ready for execution. I choose to get started on cabbage. On the order form I see that I still have to collect the seed myself from the warehouse. I can find this with the badge number that is also attached to the seed. Before the seeds end up at our warehouse, they go through a breeding process. In this process, seeds are improved, giving a specific variety characteristics. Then those seeds remain in the warehouse until a customer places an order. That’s the moment me and my colleagues jump into action. We make sure the seeds are clean for shipment. It only has to be packed and shipped after that!

The order says what kind of job I have to do, in this case a basic clean. In the picture on the right, you can see the seed with dirt, twigs, soil and damaged seeds. My job now is to clean it, but I can’t do that with just one machine. The combination of machines I choose to clean it takes care of that. I start up the lot with one machine; this takes a few hours. In the meantime, I can work on other jobs.

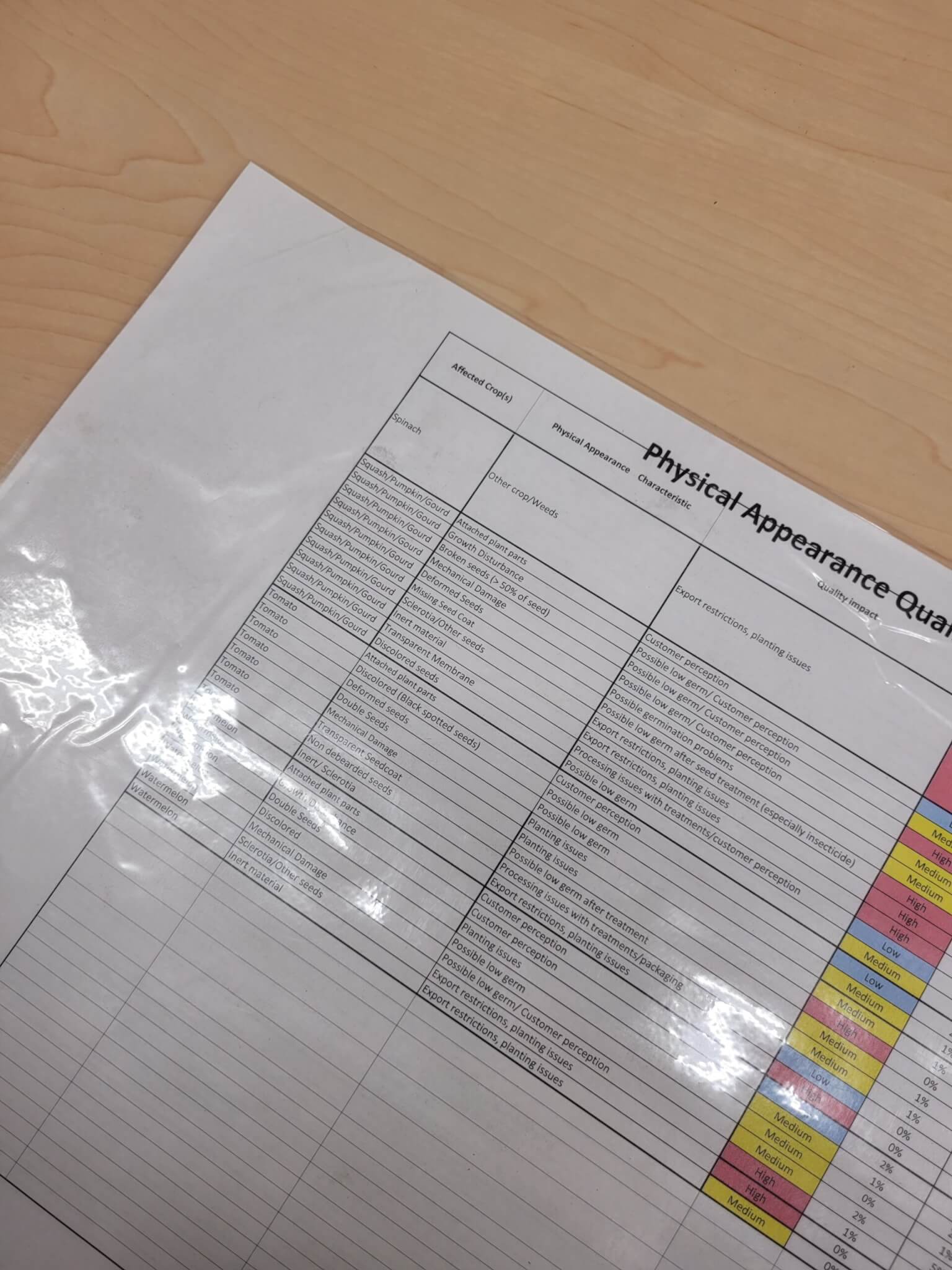

When the batch is ready, I do an inspection. Different margins apply to each variety. I now look at the criteria of cabbage to double-check whether everything is out. I can see from the margins what a batch must meet. If the lot scores a 5, the lot is good. Then, for example, 5 out of every 1,000 seeds may be wrong, think wrong size. Of course, we always try to clean the seeds as much as possible, but after going through the processes, even a 4 is good enough to send the order back to the warehouse. Below ‘4’, however, means the batch needs further cleaning.

Upgrading

In the work I do, I particularly like to do in cleaning upgrading. This is were we improve already cleaned seed lots once again. Clean-up upgrading is done when a customer has higher requirements for the seed than the ‘normal’ guidelines. For example, a customer may want more seeds to germinate. Then we have to upgrade the quality from, say, 83% germination to 85%. We always follow a protocol for that, which are on special cards. On them, in this example, I can see that 10% of the seeds have to be taken out of the batch, then the margin of germination is alright.

Why do I like this best? I can put my own creativity into it. There is room for input from my own experience. I have to think about how I want to adjust the machines so that the right margins of seed are filtered out of a batch.

As I mentioned earlier, I work with many different machines. In cleaning upgrades, I use machines that filter out light and small seeds. This is because these have less germination power than large, uniform seeds. For example, we have the gravity table (green machine). That shakes; wind comes from below; and the light seeds fall into the trays on the left and the good seeds on the right. In the machine with 1, 2, 3 and 4 on the side (see photo), for example, you can set different airflows separately from each other. This ensures that the unusable seeds are blown out of the batch. The rest of the seeds fall into the bin in front of the machine.

In the washing machine it goes

This is because the seed goes through several phases in our department: cleaning/cleaning-upgrading (removing junk and bad seeds), washing/disinfecting (washing diseases off seeds) and priming (making sure seeds hatch at the same time through temperature control, among other things). Like me, each colleague has a preferred task.

How the other process parts are doing, we discuss each day during the day’s start with the team. This is every day at 10 o’clock, after our coffee break. Then we discuss the planning, the status of all orders, whether there are any sick people, etc. Occasionally, I will also help out with other tasks, such as washing. Seeds sometimes have diseases or dormancy that need to be washed off. Fun fact: we do this with regular detergent! To kill viruses, we use heat cabinets.

Sometimes you will find me at the drying wall. After washing, the seeds go to this wall to dry. You’ll spend a whole morning on the forklift truck filling the wall with plates full of moist seeds, or taking them out.

My side hustles

Besides Operations Specialist, I hold a number of other positions within Bayer. For example, I chair the department’s housekeeping team. We look at what needs to be adjusted in the department, with safety being the top priority. For example, we recently moved our lockers because they were actually always in the way.

Next to work, I have another passion: football. I coach outside work and play football fanatically myself. It will therefore come as no surprise that I am also part of Bayer’s sports committee, with which I recently organised a successful sports day.

Seed Valley Futsal 2023

Last Saturday it was finally time again; the Seed valley indoor football tournament in the Dars (Wervershoof). Unfortunately, the last two years the tournament did not take place, but that made for all the more enthusiasm among the participants at this 11th edition. This time, the football was organised by my colleagues from Bayer.

Unfortunately, I had to drop out due to an injury shortly before the tournament. Hence, I took on the coaching together with my colleague Paul. After a good pool phase, we eventually had to face Bejo seeds in the finals. Fortunately, the ‘third half’ made up for it and we all ended this great day in a nice way!

I will round up my week of work with some beers with my friends ;). Thanks for reading!

Thanks for joining me during my work week! Together with my colleagues in Seed Valley, I work to ensure the global availability of healthy vegetables and colourful flowers. In doing so, we constantly face new challenges. The big question is: What will you do?

Check out our: Vacancies and Internships.

Or do you want to read more #intheweekof? Read #joostweek, Junior Researcher Seed Production Research at Enza Zaden in Enkhuizen.